Preventing accidents with

AI-powered hazard detection and real-time automatic interventions

THE SAFE PLACE

The Safe Place is a platform which will make construction sites, precast factories,

batching plants, logistic centers and in general working spaces, much safer for all people involved.

Monitoring machines and vehicles, lifting systems and processing plants,

in relation to workers movements and activities with a predictive approach!

KEY ADVANTAGES

AI-powered system ensuring

real-time hazard detection while fully preserving worker privacy,

meeting the highest standards of data protection

The platform records the number of risky events

within each working area, without registering individuals images

Thanks to its computer vision, AI and deep learning algorithms,

The Safe Place can easily identify:

- When a person enter in a specific area

- Which type of equipment is worn

- When a person is under a crane

- Predict trajectories and forecast collisions

The computation identifies the event and

the conditions that preserve the privacy of the operators

VIDEO DETECTION

The Safe Place analyzes the images of surveillance cameras

and is able to recognize, the following cases, in real time:

Operators under a load

during lifting/handling

Operator on the

ground

Collision between

vehicles and people

Access to

forbidden area

Operator at height

without adequate climbing harness

Wearing Personal

protective equipment

REAL TIME ALERTS AND DETECTION

HUD Projections

Display critical safety alerts directly

on vehicle windshields or glasses

Wearable Alerts

Vibrating devices ensure workers

are instantly notified of hazards

AI-Powered Interventions

Automatically stop machines to prevent

accidents in real-time

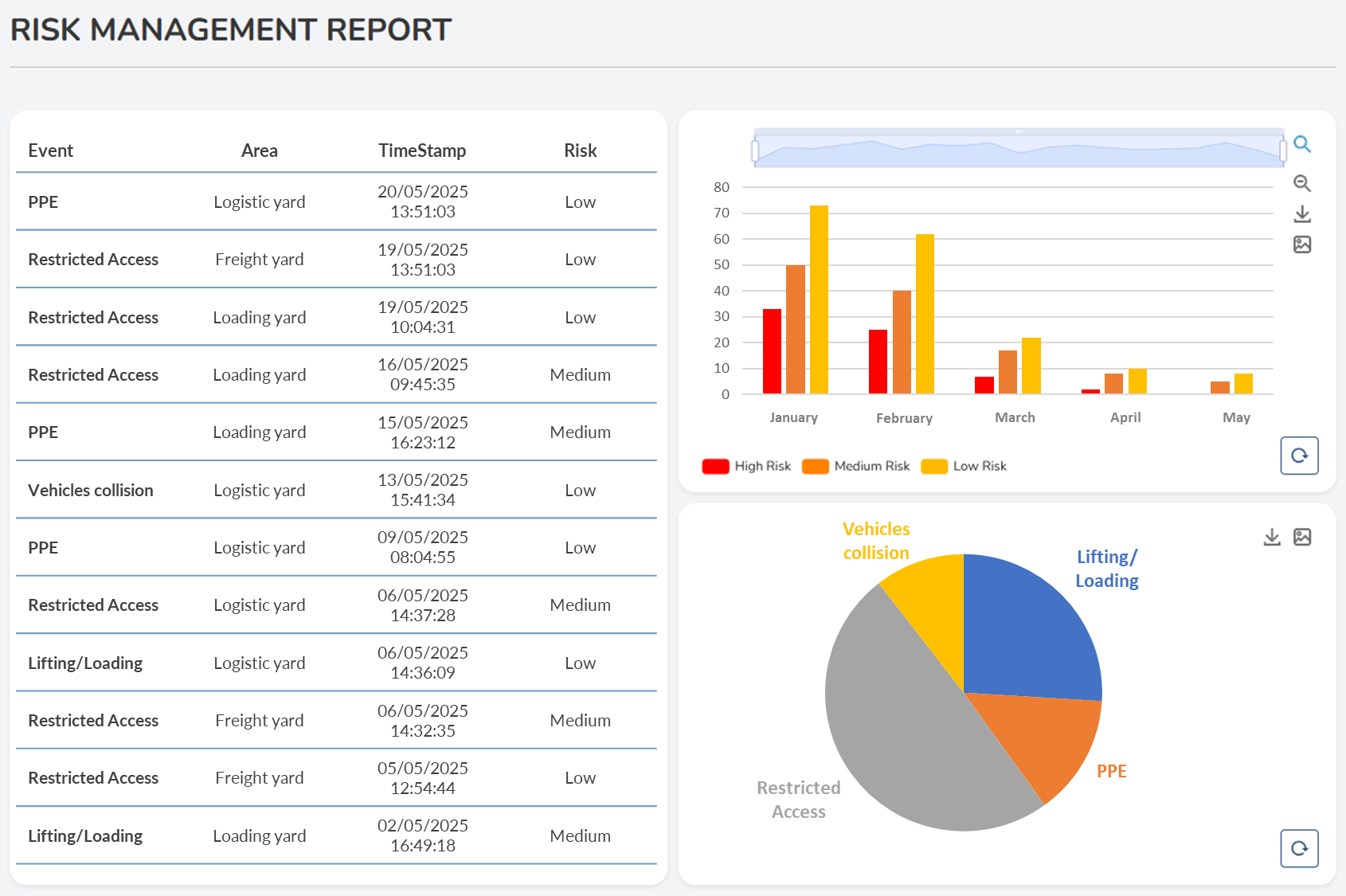

SAFETY DATABASE & REPORTING

Generation of a safety database, with the categorization

and reporting of all dangerous situations and categorization.

The security director or plant manager can access specific dashboards to view the status: